Automated process, where a diamond tip marks compression on the metal surface according to the design that is had in a computer application of metal and aluminum.

It consists of the exclusion of sand from Emery by means of a direct compressor to the material, which is previously covered with vinyl or film that blocks that area that should not be etched, allowing a natural finish to be colored.

The Transfer is a paper that has an adhesive and a silicone layer that are printed inkjet or laser to color selection and then be ironed on the material. There are two types: light and dark.

Dry engraving consists of applying the heat and pressure of a diché on a flexible substrate to create low relief. The difference of hot stamping is the application of a metallic film under the diché which results in a metallic color finish.

Refers to direct printing on the product, based on the color system CMYK: Cyan (C), Magenta (M), Yellow (Y) y Black(B)

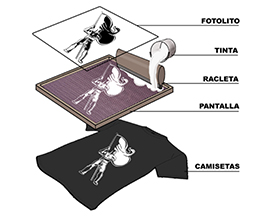

Printing system based on the transfer of images, applying dye with a squeegee through an emulsion mesh.

It is made from a printed graphic it can be in full color to which a drop of resin will be applied that offers contact and magnifying effect that is pleasing a machine to dose the high quality polyurethane resin and total transparency of the product with a three-dimensional effect With shine and protection against fading, it adheres to the metal, aluminum and plastic application surface.

The method by which a print is made on special paper or a polyester substrate consists of transferring the print to the article by means of an iron at approximately 400 ° F, the heat is responsible for transforming the ink into gas, opening the pores of the polyester, penetrating the material finishing the process cooling the pores are closed and this is the point where the impression is ready.

It consists of marking the material using a laser beam that concentrates the application of heat.

This technique uses a plate where the logo is revealed, remaining in bas-relief by means of a silicone plug, the ink deposited on the object plate is transferred.The purpose of this system is to be able to make impressions on objects that have irregular shape and in small spaces. plastic, metals and paper.

For the decoration by means of vitrify adhesive, the design is printed in silkscreen on the plane, the result of the printing is applied by means of a conveyor to the piece and it is adhered in industrial ovens at High temperature (800 ° in porcelain and 600 ° in glass ceramics) to that the special inks vitrify.